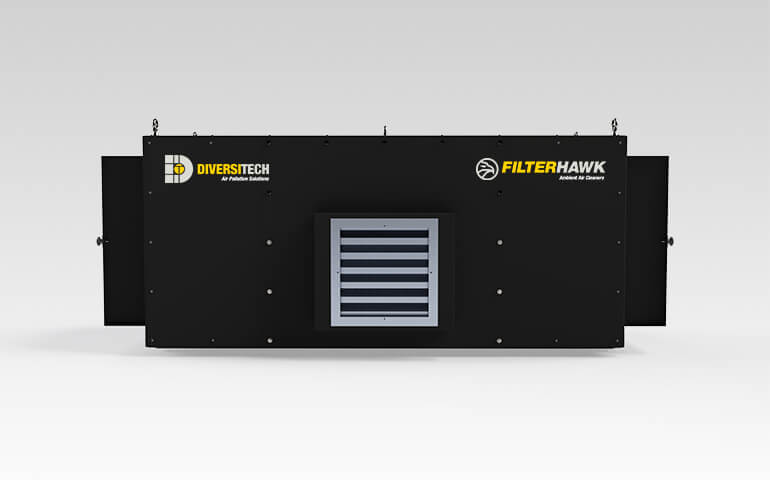

Filterhawk A-Series 3000 Ambient Air Cleaner Help & Support

Learn how to get the most out of your A-Series 3000 Ambient Air Cleaner.

See our help topics and download the A-Series 3000 Ambient Air Cleaner product guide and owner's manual.

How to..

Before You Begin

The system’s weight must be taken into account when choosing the proper installation method. Follow all applicable building and electrical codes. Mounting materials must be able to support the weight of the air cleaner plus weight of the material collected. Consult local building code for proper installation methods and materials.

Installation

There are three main ways of installing your A-Series Ambient Air Cleaner:

- Chain Hanging (eye bolts factory installed as option)

- Rod & Cradle

- Angle Braces

For optimal performance, routine maintenance is highly recommended. Do the following:

- Vacuum dirt accumulations in and around vent openings. (Dirt accumulations can cause motor overheating and a fire hazard.)

- Clean enclosed motors with an air jet (wear eye protection).

- Periodically inspect the installation. Check for:

- dirt accumulation

- unusual noises or vibration

- overheating

- worn or loose couplings, sheaves and belts

- high motor current

- poor wiring or overheated connections

- loose mounting bolts or guards

- worn motor starter contacts.

- Dayton ball-bearing motors without lubrication provision do not require periodic relubrication. Where motor has provision for bearing lubrication, lubricate as follows:

- After stopping motor and disconnecting power, thoroughly wipe the housing around both of the motor bearings, filler and drain plugs (on TEFC) ratings, remove fan cover for access to plugs).

- Remove filler and drain plugs and install a 1/8” pipe thread lube fitting in filler hole.

- Using a low pressure grease gun, pump new grease into motor until it appears at the drain hole.

- Run motor for several minutes to discharge excess grease. Shut motor OFF, replace filler and drain plugs, and reinstall fan cover.

Troubleshooting

When the motor on your A-Series Ambient Air Cleaner doesn't turn on, try the following:

- You may have a blown fuse.

- Replace with time-delay fuses.

- Check for grounded winding.

- The voltage may be too low at motor terminals due to line drop. Consult local power company.

- Increase wire gauge.

- Check for poor connections.

- The overload in motor start may have been tripped.

- Check and reset overload relay in starter.

- Check heater rating against motor nameplate current rating.

- Overload (internal thermal protector) may have been tripped.

- Check motor load.

- If motor has an automatic or manual reset thermal protector, check if tripped.

- Improper line connections.

- Check connections against diagram supplied with motor.

- Check to see if the motor is overloaded.

- Reduce load or increase motor size.

- Check the motor or starter to see if defective.

- Repair or replace motor.

- Check if the motor is overloaded. If so, reduce load. Otherwise, you may need to upgrade your motor size.

- Check the motor voltage as it may be too low. Verify that nameplate voltage is maintained.

When your A-Series unit's motor vibrates or is excessively noisy, check the following:

- Check the motor shaft to see if it’s misaligned. Realign if needed.

- The 3-phase motor may be running on single phase.

- Check for open circuit, blown fuses or unbalanced voltages.

- Voltage may be high or unbalanced.

- Check wiring connections. Consult local power company.

- The bearings may be worn, damaged, dirty or overloaded.

- Replace bearings.

- Check loading and alignment.

- Check winding to see if it’s defective. Check the shaft to see if it’s bent or bowed. Repair or replace.

- Check for a loose sheave or misaligned coupling. Tighten set screw(s); realign coupling.

If you find the airflow being generated by your A-Series unit is insufficient, check for the following possible causes:

- The blower speed may be too low. Check for correct drives.

- Check to see if the dampers or registers are closed. If so, open them.

- Inspect filters to see if they are dirty or clogged. Clean or replace them if neccessary.

- Check for leaks in duct work. Repair if neccessary.

- Check for elbows, cabinet walls, or other obstructions and correct if neccessary.

- Check for belt slippage. Adjust or replace belts if neccessary.